Today, no commentary on a fast-birthing technical field like nanotechnology a can be complete without understanding how the ecosystem

National Instruments has built on its LabVIEW platform impacts each enterprise's development, validation, production, and the process of innovation.

More than two decades after its introduction, LabVIEW's consequences for tech enterprises range from the stark (for example, ambitions of selling hardware to a technical or systems-integration community today often hinge on its LabVIEW-compatibility) to the vaguely-acknowledged (LabVIEW's global community as a crucible for innovation; LabVIEW's development speed as a competitive edge; LabVIEW's role in reducing the great unfunded liability of support; LabVIEW's libraries as facilitators for technological cross-pollination; etc., etc.).

NI's trademark is "The Software is The Instrument," and while they've certainly delivered with a comprehensive family of products and libraries, there's more to it than that, just as there's more to a university than its buildings and curriculum, more to a city than its neighborhoods and nightclubs, more to a country than its borders and monuments. Within each of these lies a certain abstraction, a culture, a churn and an energy which makes things happen.

As a LabVIEW user since its earliest version and the holder of several LabVIEW-based patents, I've been highly honored to join the Industry Experts discussion panel at the

NI Week conference in Austin in early August. The topic is Breakthrough Innovation, and the panelists will discuss how innovation takes place.

When my interest was solicited, I replied:

Looking back, NI has a track record for providing tools for folks like me to devise, develop and deploy our own wild ideas. NI has made it accessible for non-specialists to interface with and coordinate instruments, construct virtual instrumentation, and now construct their own intelligent instrumentation including custom silicon logic that runs processes synchronously and truly in parallel. Each of these represents an enabler for innovation in its own right. And I'm struck that all have been brought together under the LabVIEW framework. Maybe "The Architecture Is The Innovation"? Enabling folks to cross disciplinary boundaries and mash solutions together into groundbreaking new hybrids is one of its key benefits-- and that speaks to the "networking" aspect that is foundational to NI Week.

So: Can innovation be made to happen, and what role does the LabVIEW architecture play in that? (Or is innovation always like lightning striking, with LabVIEW playing no more of a role than a screwdriver?) Also, given that organizational, interpersonal and managerial practices can strangle innovation in its crib, what are the business-model enablers for innovation? In particular, how can cross-pollination across diverse fields happen, and how can such mash-ups be nurtured in a way that swiftly benefits customers and the bottom line?

Well. Turns out the other panelists are:

- Andrew Hargadon, author of How Breakthroughs Happen

- Suchit Jain, Vice President of Strategy, SolidWorks Corporation

- Patty Seybold, author of Outside Innovation

- Dr. James Truchard, National Instruments CEO and Co-Founder

What a rockin' group! Dr. T, of course, I first met more than twenty years ago; no finer businessman walks this earth. Jain has been very visible in the area of design and analysis software and should have much to say on how to facilitate innovation, based on his efforts to drive new tools for innovation into communities of engineers used to doing things the tried-and-true way.

But though I'd heard of Hargadon and Seybold, they were unfamiliar to me. So I've been reading up.

Frankly (and in vivid contrast to the turgid, disconnected case-analyses too typical of scholars of management) some of what they've written has made me pause and exclaim "Whoa! These folks have been reading my mind!" My own proudest work has occurred when my group somehow stumbled backwards into living examples of their customer-partnered (Seybold), combinatorial and networked (Hargadon) methodologies: when we chanced to put the customer in the driver's seat for strategy and design, when innovation followed from mashing stuff together, and when we relied on a team approach which crossed organizational, technical and social boundaries. Often we'd missed the memo that something was impossible. And that's key, too.

Hargadon and Seybold's contribution is to illuminate and illustrate the process of innovation with examples and cogent distillation. Consider the following from the foreword to Hargadon's book, in which Stanford's Kathleen Eisenhardt, coauthor of

Competing on the Edge, succinctly summarizes some of its key points:

"...From my vantage point two observations are crucial. The first is that innovation is the result of synthesizing, or 'bridging,' ideas from different domains... In short, extraordinary innovations are often the result of recombinant invention.

"The concept of bridging reveals a couple of counterintuitive points. First, whereas it may be appealing to focus on the future, breakthrough innovation depends on exploiting the past... A second counterintuitive point is that organizing structure can dominate individual creativity. ...Successful innovators are not really more gifted or creative than the rest of us. Rather, they simply better exploit the networked structure of ideas within unique organizational frameworks.

"The other crucial observation is that breakthrough innovations depend on 'building' communities..."

Exactly right.

Both Hargadon and Seybold maintain insightful and energetic blogs. See the links in my "Recommended Reading" list.

NI Week is August 7-9 in Austin and is stuffed with technical sessions and strategic discussions. The Breakthrough Innovation panel is Wednesday afternoon; check

the website a week or so in advance for schedule details. It should be a blast. Hope you can join us.

-----

UPDATE: 30 August 2007: The Industry Experts panel is now available as an online video:

http://www.ni.com/niweek/keynote_videos.htm ...click on the "Industry Experts" button.

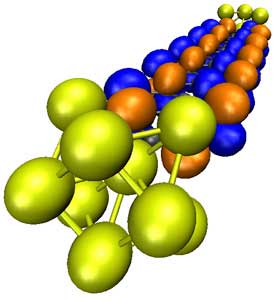

e shiny gray/silver lead sulfide crystal did in the crystal radio sets of our childhood (at least, those of us Of A Certain Age): they're leveraging the device's nonlinear voltage-to-current behavior to detect the amplitude modulation of a carrier wave, in this case a 1GHz carrier.

e shiny gray/silver lead sulfide crystal did in the crystal radio sets of our childhood (at least, those of us Of A Certain Age): they're leveraging the device's nonlinear voltage-to-current behavior to detect the amplitude modulation of a carrier wave, in this case a 1GHz carrier.